OUR PROJECTS

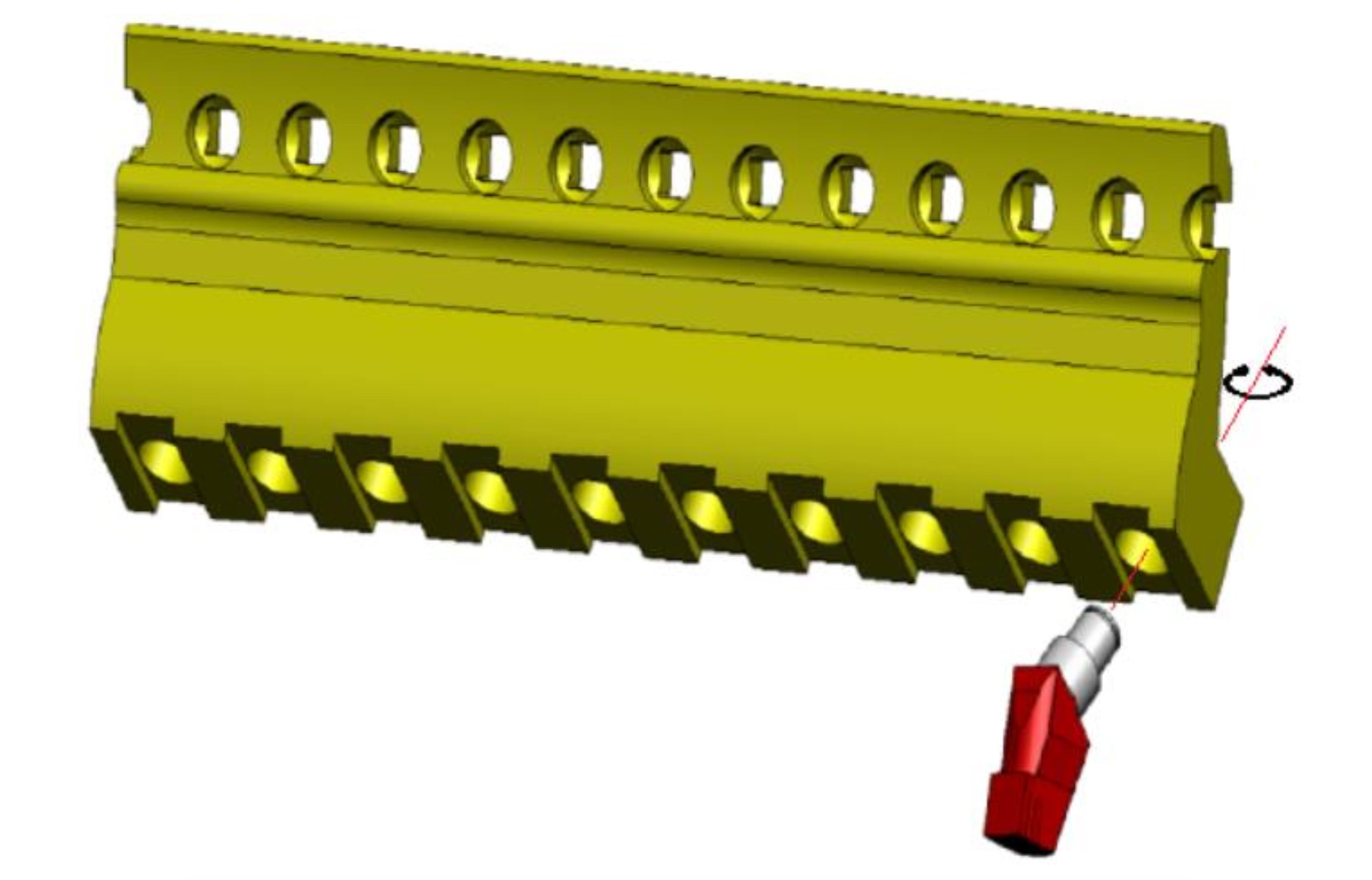

RENEGRADE TUNGSTEN CARBIDE GRADER BLADE SYSTEM

RENEGRADE SYSTEM PROVIDES 80% INCREASE IN CUTTING EDGE SERVICE LIFE.

An open cut coal mine in NSW, Australia working in often wet & abrasive conditions were looking for a G.E.T solution to condition their haul roads with a need to reduce downtime and overall maintenance costs.

Over many years, they had trialled other incumbent cutting-edge & toolboard options yet were unable to find a suitable product to provide a cost-effective solution. Through word of mouth & demonstrated performance within the local region, the miner’s maintenance team was introduced to 2MT Mining Products who offered up the 2MT Renegrade Tungsten Carbide Grader Blade System suited the 24M and haul road conditions on hand.

Over a five-month trial period, 2MT Product Support Representatives provided onsite training along with G.E.T inspection reporting to assist site maintenance teams with optimising the performance of the Renegrade solution. Upon completion of the trial period, 2MT had provided a haul road conditioning solution which demonstrated zero parts losses, decrease in production & maintenance downtime in addition to a significant cost savings over the life of the trial. This successful trial saw a roll out of the 2MT Renegrade System across their fleet of 24M Graders.

PROFILE

Application: Haul Road maintenance

Commodity: Coal

Conditions: Wet & abrasive

Machine: Motor Grader

Make & Model: CAT 24M

Challenge

Eliminate G.E.T loss events

Improve machine availability

Provide increase in G.E.T wear life

Achieve safe service interval G.E.T changeouts

Product Solution

Renegrade Tungsten Carbide Grader Blade System

Results

80% increase on G.E.T service life

Zero G.E.T loss events

Improved machine availability

Safer & less frequent G.E.T interactions

Met major service interval G.E.T changeouts.